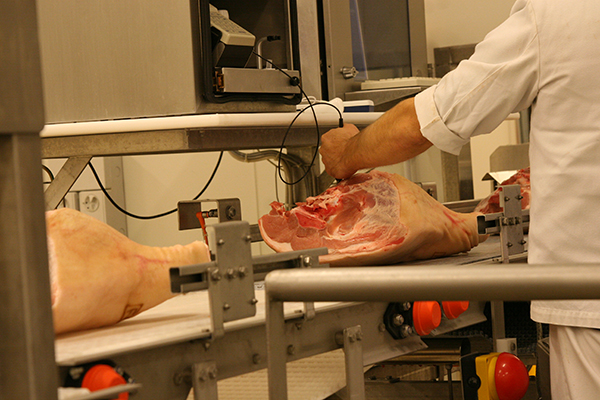

For more than 40 years, Fives Syleps has been involved in the management, handling and storage of materials in all transforming processes, particularly in the cutting units of the food industry. Perfect process control combined with a range of equipment adapted to the constraints of the business, enables Fives Syleps to offer complete turnkey solutions

Thanks to our experience but also thanks to ergonomic and productivity studies that we have carried out with our customers and specialized design offices, we offer a wide range of cutting and packaging lines specially adapted to the trade of processing meat and fish.

Benefits and built-in features:

Fives Syleps designs and manufactures a complete range of conveyors specially adapted for the handling of bare products and containers for processing and cutting meat and fish plants.

Integrated advantages and features of the CILS conveyor range (Sanitable washable stainless steel conveyor):

Fives Syleps has been managing automated storage solutions for about 30 years. The latest generation of automated storage called Flex’Y Shuttle is specifically dedicated to bare product production environments, requiring regular washing and disinfection operations.

This solution consists of multi-level shuttles with a maximum height of 3 m and can be stacked up to 10 Flex’y Shuttle maximum.

Benefits and built-in features:

high-performance processes on material management in the meat industry: